Linen tracking with RFID tag

Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags attached to linen items. The tags contain electronically-stored information.

This technology is used to help hotels deal with the challenges related to linen management. The Linen Management System is specifically designed to automate linen operations in housekeeping departments of hotels. With RFID technology, the system can reduce the time and effort involved in processing linen and taking labor intensive inventories.

The boiler, heart of a laundry

Our plant at Cassis runs on a main 10 tons per hour capacity John Thompson steam boiler. This one is backed up by three standby oil fired units, one of 8 tons and two 4 tons’ capacity in case of breakdown or maintenance. Furthermore, a steam header has been installed, enabling us to isolate any part(s) of the factory for more efficient supply.

Tunnel washers

With a total of 5 tunnel washers, we are able to have dedicated washing processes and specific departments for each of the following items:

– Beach towels

– Room towels

– Bed linen

– Food and Beverages

– Healthcare

Ironers

We have a total of 9 industrial ironing calenders of up to 4m wide.

Bedsheets, pillow cases, food and beverage items… all have different sizes and finishing requirements. Our wide range of ironers allow us to deliver the best quality ironing to the largest and more complicated items to process.

Finishing equipments

We have 8 of the best universal and versatile form finishers from Barbanti, a reference in mannequin ironing.

Finishing perfection for shirts and outerwear. Besides the typical performances of form finishers with pneumatic sleeve tension, these machines offers the big advantage of clamping the garment lower part, tensioning it to keep it perfectly stretched during the finishing process.

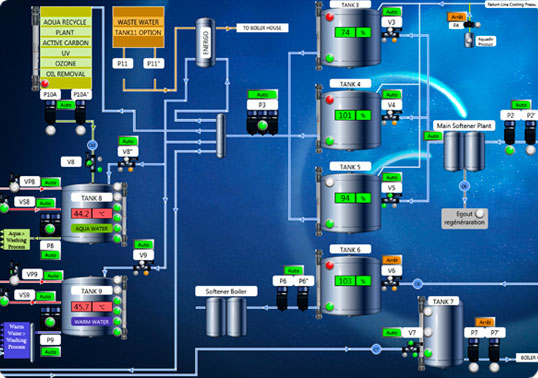

WECO

Water & Energy Consumption Optimisation

DCS now runs on a state of the art, fully automated water & steam network.

Our touch-screen interface allows us to remotely monitor and control this network to constantly optimise the water and energy consumption of the factory.